Stokbord® Drum cable protection Installation for Dogger Bank Wind Farm (A & B)

Stokbord® Drum has shown its strength once again on one of the world’s largest renewable energy projects – Dogger Bank Wind Farm. Funded by SSE Renewables, Equinor and ENI, Dogger Bank Wind Farm will be the largest wind farm in the world, and once complete it will be capable of powering over 6 million homes in Britain.

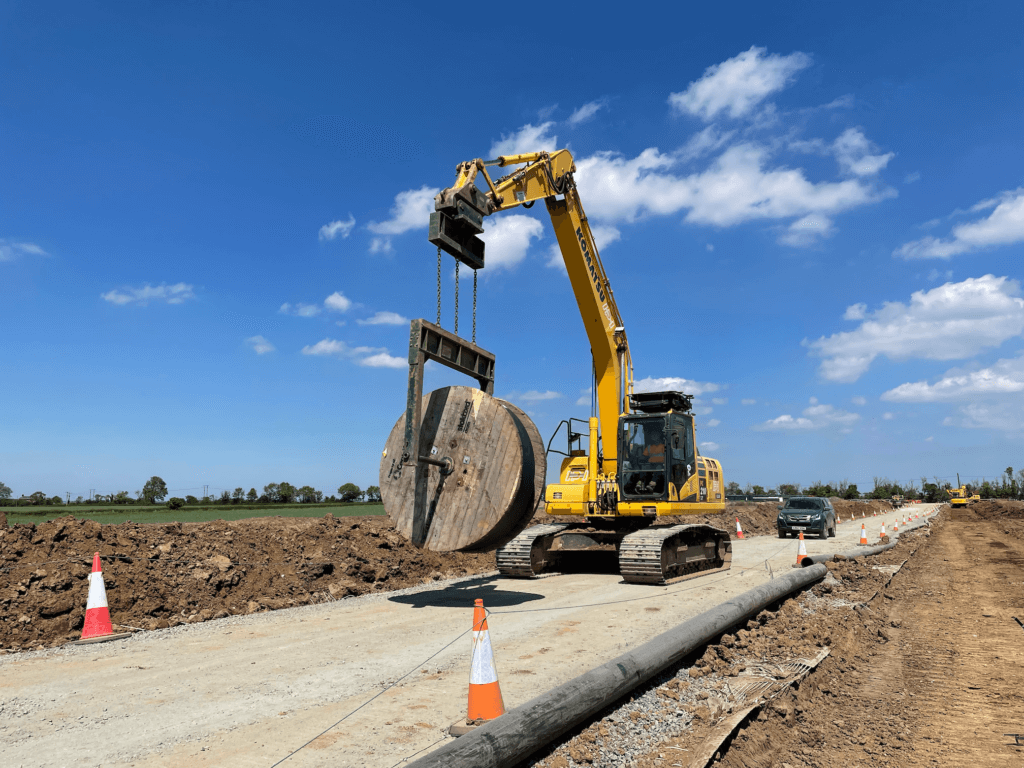

As always, great infrastructure needs great protection. Centriforce are proud to share that Stokbord® Drum has been installed as part of the cable protection system for Dogger Bank Wind Farm (A & B). Stokbord® Drum delivers heavy-duty utility protection in a single material strip, allowing operatives to install cable protection directly into the trench without needing to set foot into it. We wind our protection material directly onto an industrial reel which allows users to unroll the material into application, providing significant health and safety benefits alongside major time and cost savings. These specifications make Stokbord® Drum the perfect partner for large scale projects as heavy-duty cable protection can be installed in a matter of minutes without the need for individual peg connection as required by traditional protection tiles.

We met with Jones Bros Civil Engineering on the East Riding Cable Route for Dogger Bank Wind Farm (A & B) to see how Stokbord® Drum supported their team on this project.

Commenting on the speed of installation, James Lockwood – Project Manager for Jones Bros Civil Engineering says “It is estimated we can install 250 metres of Stokbord® Drum within 3 minutes, using 2 men. In comparison, it could take up to 90 minutes using 4 operatives and traditional plastic covers.” On this project, Stokbord® Drum has allowed operatives to install cable protection up to 30x faster than traditional methods. This is an incredible advantage for contractors. With fewer operatives required to work on a single 250m stretch of cable, Stokbord® Drum saves time and costs by allowing more operatives to cover greater distances in a shorter space of time.

Watch Stokbord® Drum in action on-site:

Key Benefits of Stokbord® Drum:

- Ease and speed of installation – up to 30x faster to install than traditional plastic covers

- Significant reduction in manual handling costs

- Supports health & safety on-site

- Removes the need for workers to set foot in the trench

- Reduced risk of injury and accidents in trenches

Centriforce’s CEO Simon Carroll comments “We are very proud to support Dogger Bank Wind Farm with one of our greatest innovations, Stokbord® Drum. Centriforce developed Stokbord® Drum through our policy for continuous improvement, working directly with our trusted customers and partners to overcome the challenges frequently faced when installing heavy duty cable protection. Stokbord® Drum delivers an easy-to-install solution that greatly increases application speeds while reducing the risk of injury and accidents occurring on-site. This product capability is perfectly matched to large scale projects such as Dogger Bank Wind Farm – enabling significant time and cost savings in every kilometre.”

As well as Dogger Bank, Stokbord® Drum has been installed on major infrastructure projects including Triton Knoll, Hornsea 2, Seagreen and Viking Link. Centriforce looks forward to supporting more partners on major utility projects in the future.

For enquiries on Stokbord® Drum, get in touch with our team via email sales@centriforce.co.uk. Telephone +44(0) 151 207 8109 or our contact page today.