Our Recycled Plastic Manufacturing Process

How we Manufacture our Recycled Plastic Products

Operating for over 40 years, Centriforce Products Ltd continues to be one of leading British recycled plastic manufacturers & reprocessors

We are proud to have been one of the UKs pioneers of plastic reprocessing and recycling, with an innovative process which continues to create class leading reprocessed plastic products. You can also be sure that we take our contribution seriously – diverting perfectly workable plastic from landfill in a time where environmental consciousness has never been so important.

Our Recycled Plastic Materials & Recycling Processes

Historically, Centriforce has been a pioneer of LDPE recycling with an innovative LDPE production process where we sorted and recycled low density polyethylene film. However, we now do things a little differently.

For the majority of our LDPE recycled products, such as Tapetile ® and Stokbord ®, Centriforce purchases 100% recycled plastic pellets from a range of trusted suppliers. This enables our team to now focus on product development, innovation and increasing our process efficiency.

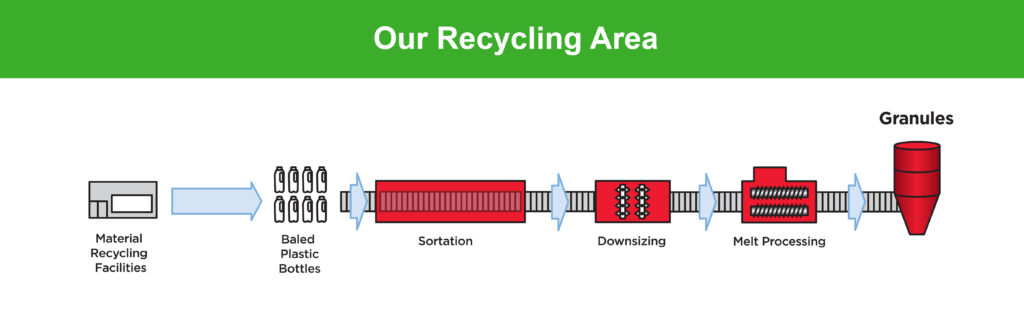

Centriforce continues to recycle and process HDPE feedstocks on-site for our range of Duraplas products. By processing high-density polyethylene post-consumer waste, we continue to set ourselves apart as one of the leading British recycled plastic companies as we are diverting plastic from landfill and reducing the export of discarded recyclable materials.

We recycle all plastic waste generated during our operations. This goes back through our process so that no plastic material is sent out to landfill.

Our Circular Economy Practices and Closed Loop Scheme

Centriforce is committed to working with our customers to explore potential closed loop solutions. We will consider proposals from customers using our material where we can contribute towards their HDPE and LDPE recycling processes.

Our products are 100% recyclable after use which extends the life of plastic material even further so that we can maintain our contribution to circular economy practices.

To discuss how Centriforce can support your business in utilising your waste HDPE and LDPE plastic materials, we advise customers to contact our team for more information.

End Products of our Recycled Plastic Manufacturing Processes

Centriforce manufacture items that are ready for end-use, such as Stokbord® Covers, Stokbord Drum and our Locata range. Some of our industrial plastic products, particularly Duraplas and Stokbord Sheet, are also used as components that are further processed and fabricated for a wide variety of applications.

From boardwalks and community benches to ecological fencing, Centriforce has been proud to support a diverse range of projects.

Most of the end products of our recycled plastic processes are utilised in a similar way to traditional materials such as plywood, timber, steel and even aluminium. Our range of products tends to offer a more sustainable and cost-effective option to virgin plastic for many applications.

We take care when sourcing plastic utilised as part of our HDPE and LDPE recycling processes. We carefully select our plastic feed-stocks to produce high specification, technical products which meet our customers’ needs and expectations.